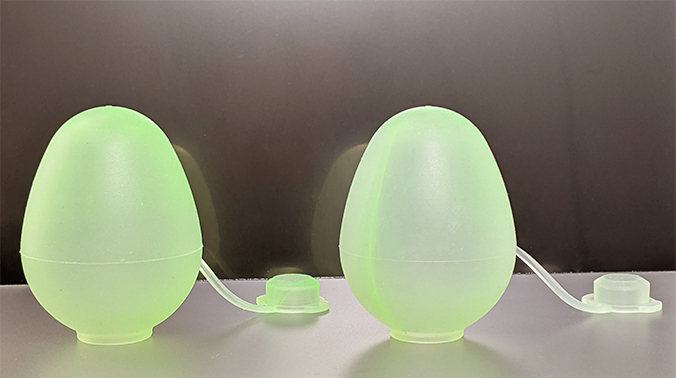

The Superiority of Piston Needle Valve System

- Maximum use of raw material

Different from conventional runner and sprue, the piston needle valve is closed after the exact amount of LSR (Liquid Silicone Rubber) has been injected into the cavity, then prevents producing wastes while manufacturing.

- Minimum time of LIM (Liquid Injection Molding)

Without having to consider the curing time of the runner and sprue, the cycle time is decreased, then remarkably increases the capacity.

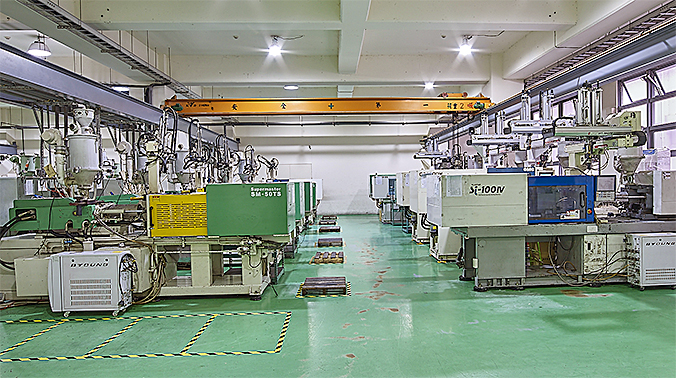

How Does H.R. Take the Piston Needle Valve System to the Next Level?

Combine the superiority in piston needle valve systems and conventional open nozzle systems,

H.R. has developed its exclusive technology - the novel open nozzle system.

Click here to learn more about how H.R. achieves the ultimate performance of efficiency.